Sherardizing Outline

Zinc has been used for over a century to enhance the longevity and performance of steel due to its intrinsic resistance to corrosion.

Sherardizing is a method of producing a long term protective Zinc-Iron alloy coating on iron and steel, thus giving superlative protection against corrosion and abrasion in numerous industries.

Sherardizing also produces an ideal surface for other processes such as rubber to metal bonding and the application of organic coatings, oils, stains, lubricants and sealants. The coating is ideal for both small and larger parts that require inside diameters and internal faces coated without the need for any remanufacturing or rethreading operations.

Ultimately, Sherardizing provides a cost effective, higher performance, reliable alternative to Hot Dip Galvanising.

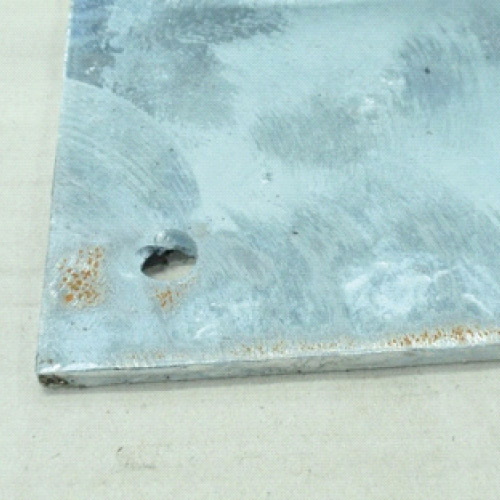

Before

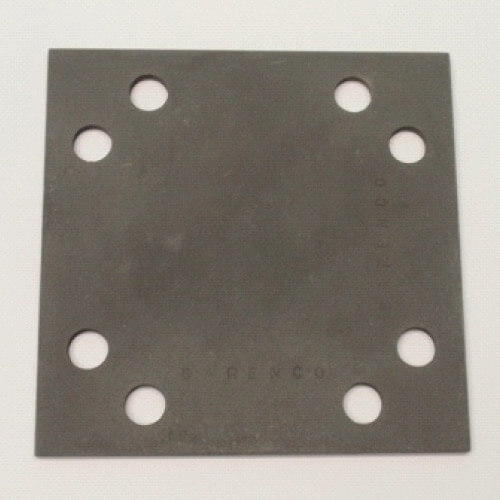

After

These pictures were provided to us by a long trusted client, providing tangible examples of issues wformed by galvanising demonstrated through:

- Bad Surface Finish

- Blocked Holes/Contours

- Components Stuck Together

Our clients’ issues were eliminated by switching to a Sherardized coating that we provided, shown on the subsequent pictures.